Kerawax 4600 is a paraffin blend specifically developed for making pillar candles and wax melts. Benefits of this wax are:

- Outstanding stability with no experienced shelf life issues.

- Produces structural candles with a smooth shiny finish.

- Provides an excellent scent throw, both hot and cold.

- Works well with silicone moulds and releases easily.

- No animal or GMO products are used in this wax.

- Provides excellent hot and cold scent throw.

- Produces vibrant colours with minimal dye.

- Can take a fragrance load of up to 10-12%*

- Not tested on animals in its manufacture.

- Also a great choice for melts and tarts.

- Arrives in pellet form for ease of use.

- Fast cure time of 24 hrs.

- Requires no additives.

*The CLP we provide with our fragrance oils is for use up to 10%. A new CLP would be needed if the full 12% is used.

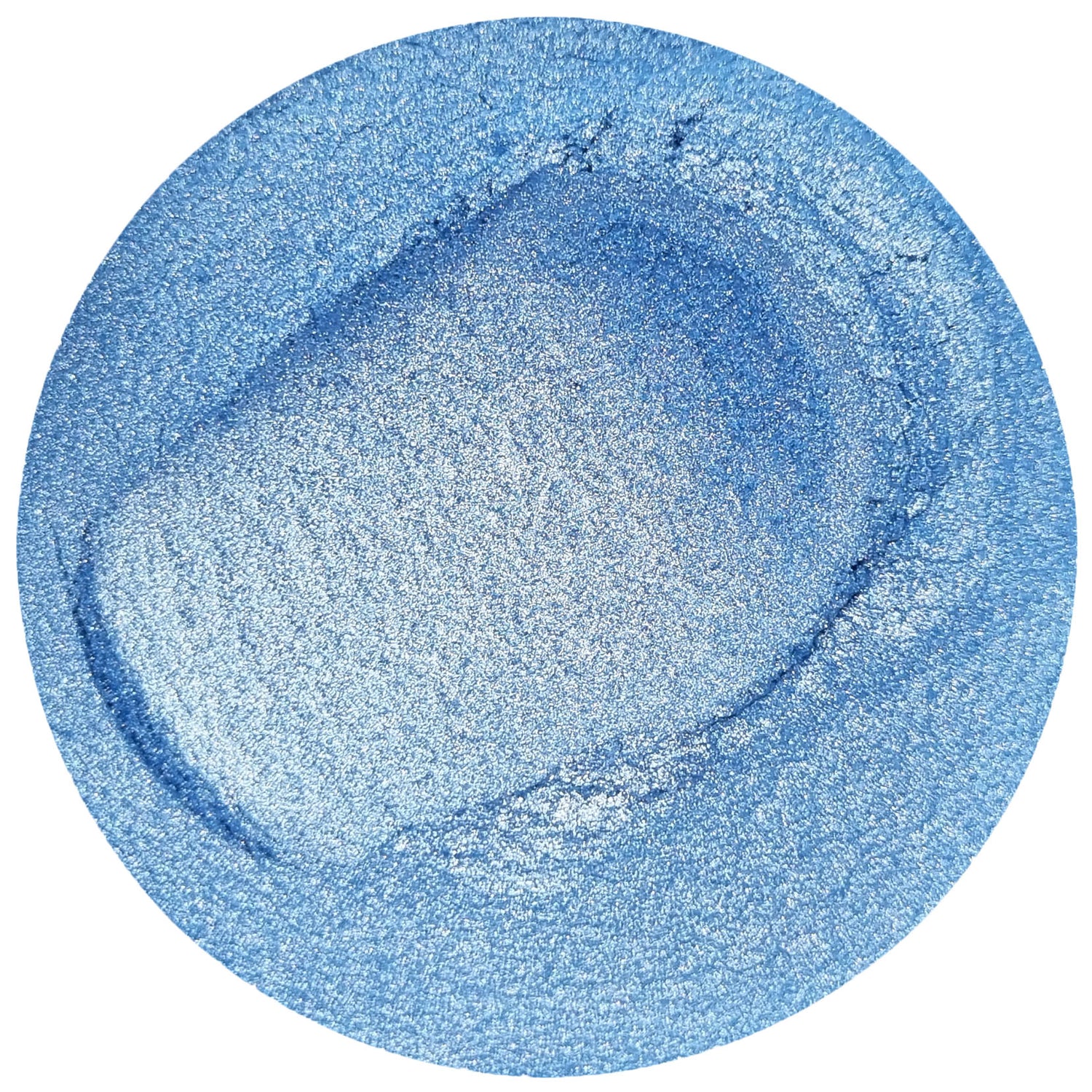

Colour

The wax should be melted to around 80°C when using dyes to ensure it fully dissolves into the wax. We recommended that moderate stirring is carried out. For powder dye use, heat the wax to 90°C, add the dye and mix until dissolved. When not including dyes, melting the wax to 70°C will be sufficient. Note: Pigments do not dissolve in Kerawax 4600.

Moulds

Moulds should be clean and free of contaminants. They should be at least at room temperature, although pre-heating them to approx. 45 - 50°C can be beneficial and adds a glossy finish.

Fragrance / Pouring

Add your fragrance oil as close to a pour temperature of 65°C as possible for optimum results and mix immediately prior to pouring. If you experience difficulties with your pour temperature, try a lower or higher temperature in increments of 5 - 10°C.

Minimise the time that the wax is at a high temperatures in order to reduce burning off the fragrance.

Double-Pour

Two pours are required with larger candles such as 3 & 4 inch pillars. Do the first pour at 65°C by filling the mould to the top and allowing the candle to cool until it’s still warm with a congealed center that has no liquid. If the top of the mould (bottom of the candle) has “skinned” over and left a void inside, poke two holes into the candle near the wick and pour a second time at 60°C.

Wicking

This wax may require larger wick sizes than traditional paraffin waxes. They tend to burn more down than out allowing them to have longer burn periods. Scent, colour and candle configuration have a great impact on the best wick choice. Too large of a wick may cause sooting, accelerated burn times and guttering (wax leaking through the side of the candle). Too small a wick will cause tunneling and produce a smaller flame. Keep wicks trimmed to ¼ inch. If you experience poor flame quality or stability, try a different type of wick.

Cooling / Test Burning

Cool undisturbed candles at room temperature (about 25°C) for 48 hours before test burning. The moulds should be about ¼ to ½ inch apart to allow air circulation for even cooling. If difficult mould release is experienced, placing the mould / candle in the refrigerator for a few minutes will cause the candle to release. Test burn the candle for burn pool diameter and “mushrooming”. Mushrooming is when carbon and/or other substances build up on the end of the wick interfering with combustion. Mushrooming can cause sooting and poor odours. Try different wicks until you have your desired burn pool diameter and a good clean flame.

Curing Time

Paraffin wax typically has a cure time of 24 hours.

Safety Data Sheet (SDS) and Technical Data Sheet (TDS) are both available to download below.

SDS

SDS  TDS

TDS